Background

Imwe vhezheni itsva yeUL 1642 yakaburitswa. Imwe nzira kune inorema bvunzo bvunzo inowedzerwa kune masaru ehomwe. Izvo zvinodikanwa ndezvi: Kune pouch cell ine huwandu hwakakura kupfuura 300 mAh, kana ikapfuura iyo inorema bvunzo bvunzo isina kupasa, vanogona kuisirwa Section 14A round rod extrusion test.

Pouch cell haina nyaya yakaoma, iyo inowanzo tungamira mukutsemuka kwesero, kutsemuka kwepombi, marara achibhururuka kunze uye kumwe kukuvadzwa kwakakomba kunokonzerwa nekutadza muyedzo inorema, uye inoita kuti zvisakwanise kuona yemukati pfupi yedunhu inokonzerwa nekukanganisa dhizaini kana kukanganisa maitiro. . Iine round rod crush test, zvinokwanisika kukanganisa muchitokisi zvinogona kuonekwa pasina kukuvadza sero chimiro. Kudzokororwa kwakaitwa nemamiriro ezvinhu aya mukufunga.

Testing flow

- Sample inobhadharwa zvizere sekukurudzirwa nemugadziri

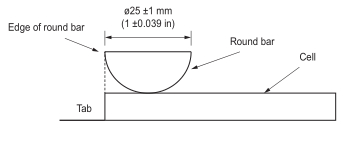

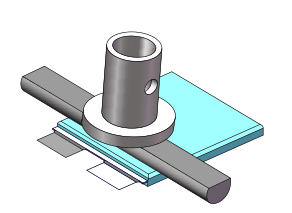

- Isa muenzaniso panzvimbo yakati sandara. Isai simbi yakatenderera ine dhayamita ye25±1mm pamusoro pemuenzaniso. Mucheto wetsvimbo unofanirwa kuenderana nechepamusoro pesero, ine vertical axis perpendicular to the tab (FIG. 1). Kureba kwetsvimbo kunofanirwa kunge kuine 5mm yakafara pane yega yega yega yemuenzaniso wekuyedza. Kune maseru ane positive uye negative tabu kumativi akatarisana, rimwe nerimwe divi retabhu rinoda kuongororwa. Rutivi rumwe norumwe rwetabhu runofanira kuyedzwa pamasampuli akasiyana.

- Kuyera ukobvu (tolerance±0.1mm) yemasero ichaitwa isati yaedzwa zvinoenderana neAppendix A yeIEC 61960-3 (Secondary masero nemabhatiri ane alkaline kana mamwe asiri acidic electrolytes - Inotakurika yechipiri lithium masero nemabhatiri - Chikamu 3: Prismatic uye cylindrical lithium yechipiri. masero nemabhatiri)

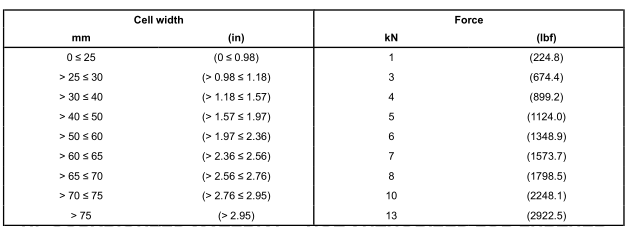

- Zvadaro kusvina kumanikidza kunoshandiswa padanda rakatenderera uye kutama munzira yakatwasuka kunonyorwa (FIG. 2). Iyo inofamba yekumhanya kwendiro yekutsikirira haifanire kunge yakakura kupfuura 0.1mm / s. Kana deformation yesero yasvika 13±1% yehukuru hwesero, kana kumanikidza kunosvika kune simba rinoratidzwa muTable 1 (akasiyana maseru ukobvu anowirirana neakasiyana masimba esimba), misa ndiro yekusimuka uye uibate kwe30s. Muedzo unopera.

- Hapana moto kana kuputika kwemasampuli.

Ongororo yekuedza

- Kusarudzwa kwenzvimbo yeextrusion: iyo pole tab nzvimbo inowanzo inzvimbo isina kusimba yebhegi sero, uye nzvimbo yetabhu inotakura kushushikana kukuru kana kudzvanywa. Zvikonzero ndezvi:

a) Ukobvu husina kuenzana kugovera (hukobvu husina kuenzana pakati pedanda tab uye chinhu chakatenderedza chinoshanda chinotungamira kune kusaenzana kwekushushikana kwekugovera)

b) Welding mamakisi munzvimbo yetabhu (kushushikana kwekugovera panzvimbo yeweld uye isiri-weld point)

- Kusarudzwa kwetsvimbo yakatenderera: Iyo dhayamita yetsvimbo yakatenderedza ndeye 25mm. Kukosha uku kunosarudzwa kuvhara nzvimbo yese yedanda tab muchitokisi (kunyanya nzvimbo inovhara pole tab solder joint).

- 13±1% deformation: Parizvino, iyo thinnest sero ukobvu pamusika ndeye 2mm. Nekuda kwesimba rekuvharirwa kwebhatiri kana kurongedza maitiro, ingangoita 8% mhando yemhando inodiwa kuti compression kune pole tab solder joint, asi inotungamira zvakananga kumagetsi emagetsi kana shanduko yemhando yakakura kwazvo. Kukosha kwe13±1% yakasarudzwa mukudzokorora uku, zvichireva kusiyanisa kwepakati 15% muyedzo yeextrusion muIEC 62660-3.

- Sarudzo yemuenzanisiro: Zvinofanira kucherechedzwa kuti bvunzo iyi ndeyemabhegi maseru ane huwandu hwakakura kupfuura 300mAh uye asina kurohwa nezvinhu zvinorema. 5 samples inodiwa. Cylindrical kana prismatic maseru uye masaru ehomwe anorohwa nezvinhu zvinorema aren't inofanirwa kutariswa pabvunzo iyi.

Summary

Iyo itsva round rod extrusion test yakasiyana neyokutanga extrusion test yeUL 1642. Yekutanga extrusion test ndeye kushandisa flat extrusion, uye kushandisa nguva dzose 13kN simba pasina kubata nguva. Inoshanda kune ese marudzi esero. Uyu muedzo unoongorora simba remagetsi resero rose (kusanganisira nyaya) uye kukwanisa kwayo kutsungirira kushushikana kwemagetsi; nepo denderedzwa rodhi extrusion inongoedza chikamu chesero, iyo diki nharaunda yeindenter ichaita kuti kushushikana kwemukati kuomerwe, zviri nyore kutungamira kudunhu pfupi remukati. Kunyanya, nzvimbo ye extrusion inosarudzwa munzvimbo isina simba ye pole tab welding, iyo inogona kuongorora zviri nani kushanda kwekuchengetedza kwesero.

Parizvino, iyi denderedzwa rodhi nzira inoshandiswawo muextrusion test yepouch cell muGB 31241. MCM ine ruzivo rwakapfuma rwekuyedza mukushanda uku.

Nguva yekutumira: Nov-16-2022